It is continuous fluid bed dryer with large production, suitable for the powder and granule materials drying and cooling of chemical, pharmacy, food, dehydrated vegetables, grain, mineral industries, like: citric acid, aginomoto, borax, ammonium sulfate, compound fertilizer, turnip strip, soybean meal, distillers' grains, seeds, slag, granulated sugar, etc.

At the core of our products, vibratory fluid bed dryer with its excellent performance are sold at home and abroad, win the trust of many customers.

Appilcationchemical industry food industry

Photo Gallery

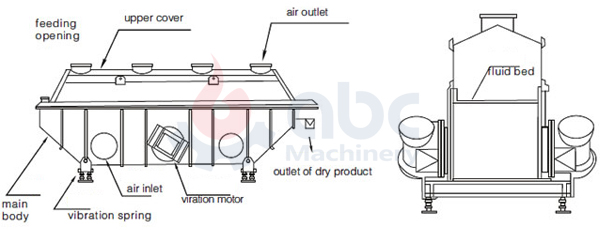

Sketch Chart of Vibratory Fluid Bed Dryer

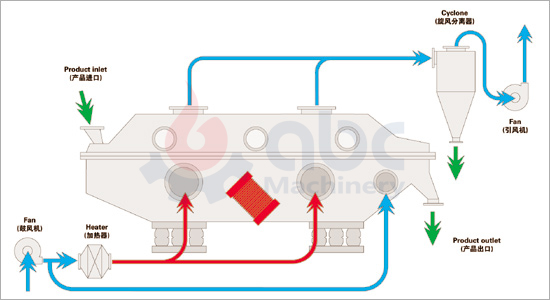

Work Flow Diagram of Vibratory Fluid Bed Dryer

Features of Vibratory Fluid Bed Dryer

- The vibration source adopts the vibrating motor to drive, so the running is stable, the maintenance is convenient, the noise is low and the life span is long.

- The fluidization state is uniform, and there is no dead gaps and broken phenomenon, it can dry and cool the materials uniformly.

- It is good in adjustment and wide in application. The change of thickness of material layer, moving speed in the machine and full amplitude can adopt infinitely adjustment.

- The damage to the materials surface is small, and it can be used to dry the fragile materials; if the granule shape is not regular, the process effect won’t be affected.

- It adopts fully enclosed structure, which prevents the cross pollution between the materials and air, so the working environment is clean.

- The mechanical and heat efficiency are high, the energy saving effect is good, that saves about 30-60% of energy than the common drying devices.

| Model | Area of Fluidzed-bed (M2) | Temperature of inlet air(℃) | Temprature of outlet (℃) | Capacity to vapor moisture (kg/h) | Vabration motor | |

|---|---|---|---|---|---|---|

| Model | Power(kw) | |||||

| GC-ZLG3×0.30 | 0.9 | 70-140 | 40-70 | 20-35 | ZDS31-6 | 0.8×2 |

| GC-ZLG4.5×0.30 | 1.35 | 70-140 | 40-70 | 35-50 | ZDS31-6 | 0.8×2 |

| GC-ZLG4.5×0.45 | 2.025 | 70-140 | 40-70 | 50-70 | ZDS32-6 | 1.1×2 |

| GC-ZLG4.5×0.60 | 2.7 | 70-140 | 40-70 | 70-90 | ZDS32-6 | 1.1×2 |

| GC-ZLG6×0.45 | 2.7 | 70-140 | 40-70 | 80-100 | ZDS41-6 | 1.5×2 |

| GC-ZLG6×0.60 | 3.6 | 70-140 | 40-70 | 100-130 | ZDS41-6 | 1.5×2 |

| GC-ZLG6×0.75 | 4.5 | 70-140 | 40-70 | 120-140 | ZDS42-6 | 2.2×2 |

| GC-ZLG6×0.9 | 5.4 | 70-140 | 40-70 | 140-170 | ZDS42-6 | 2.2×2 |

| GC-ZLG7.5×6.0 | 4.5 | 70-140 | 40-70 | 130-150 | ZDS42-6 | 2.2×2 |

| GC-ZLG7.5×0.75 | 5.625 | 70-140 | 40-70 | 150-180 | ZDS51-6 | 3.0×2 |

| GC-ZLG7.5×0.9 | 6.75 | 70-140 | 40-70 | 160-210 | ZDS51-6 | 3.0×2 |

| GC-ZLG7.5×1.2 | 9 | 70-140 | 40-70 | 200-260 | ZDS51-6 | 3.0×2 |