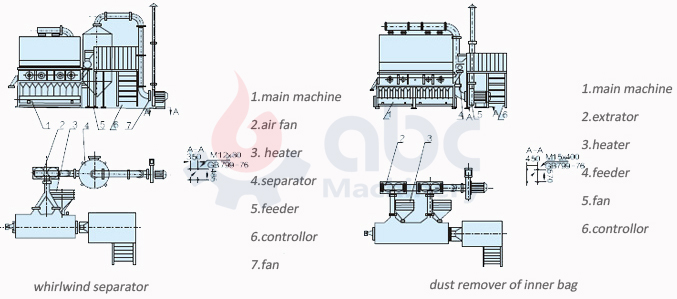

It's a kind of conventional fluidized bed drying, also calling for high-efficiency boiling dryer, which consists of air filter, fluid bed, cyclone separator, bag dust collector, high pressure centrifugal fan, and the operating floor.

In general, handling the large proportion of materials just only need to choose the cyclone separator. Handling the light proportion of materials need choose the bag dust collector equipped with pneumatic conveyor. There are two kinds of operation types: continuous and intermittent mode.

Appilcationchemical industry food industry

Two Kinds of Different Style of Fluidized Bed Dryer

Working Principle of Fluidized Bed Dryer

The clean hot air will enter into the bed through distribution of valve plate. The wet raw material fed through feeder will form boiled state caused hot air. Because of the extensive contact with the hot air and material, increase the heat mass transfer process, it only needs in a relatively short period of time to dry.

Materials feed from one end of the fluidized bed body, after a few seconds to a few minutes to dry, then automatically discharge from another head out of the fluidized bed body. In general, the equipment will be operated at negative pressure.

Applications

The drying process of medicines, chemical raw materials, grain processing, feed. Like: bulk drug, press tablet granules, Chinese traditional medicine granule, health food, drink powder, maize germ, feed, plastic resin, citric acid and other powder materials. The proper materials grain size is about 0.1-0.6mm. The best size is 0.5-3mm.

| Model | Output(kg/h) | Power(kw) | Air pressure(pa) | Blowing Rate(m^3/h) | Tem.of inlet air(℃) | Max. consumption(J) |

|---|---|---|---|---|---|---|

| GC-XF10 | 10-15 | 7.5 | 5.5×10^3 | 1500 | 60-200 | 2.0×10^8 |

| GC-XF20 | 20-25 | 11 | 5.8×10^3 | 2000 | 60-200 | 2.6×10^8 |

| GC-XF30 | 30-40 | 15 | 7.1×10^3 | 3850 | 60-200 | 5.2×10^8 |

| GC-XF50 | 50-80 | 30 | 8.5×103 | 7000 | 60-200 | 1.04×10^8 |