Vacuum Tray Dryer Design

The vacuum tray dryer is a machine mainly used in pharmaceutical, chemical and food industry. It is used to dry thermal sensitive material or materials which are sensitive to oxygen.

As the name suggests, this device consists of 3 to 96 trays within it which comes in different price ranges according to the different number of trays or shelves it holds. The type of these devices available in market are 12 trays, 24 trays , 48 trays or 96 trays.

Features of vacuum tray dryer design

- The vacuum tray dryer design is a very innovative and technically which is used to vacuum dry sensitive materials.

- At first sterilization is conducted which eliminates any harmful objects or organisms present in the material and then it is placed in the dedicated trays and applied static vacuum on.

- Use of static vacuum over these material helps eliminating the configuration damage of the material and thus is a very popular device to use in the pharmaceutical, chemical and food industries.

- It also dries some very hygroscopic substances dried to very low moisture content levels.

- Vacuum tray dryer design is the sole possible reasons for drying lumpy, glutinous product or product of low pomposity.

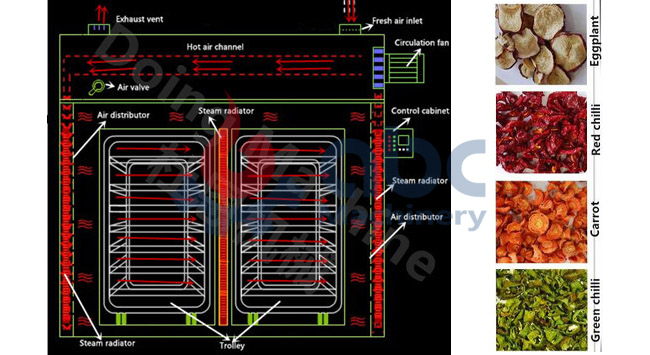

Vacuum tray dryer design working principle

The vacuum tray dryer design is the most common batch dryer which comes in two shapes- box shaped and cylindrical shaped with a facility of loading and unloading via a fixed door. Inside the device several heating plates are mounted above one another on which the heat and oxygen sensitive materials which are to be dried are placed. The top end of the trays and the bottom end of the trays are made smooth in order to permit optimum heat transfer between the plates and the product. In order to avoid retro gate condensation, the cabinet walls are indirectly preheated by limpet coil attached on the outer side of the body. After an optimum temperature is attained the cabinet is evacuated and vacuum is applied to perfectly dry the component materials.

Preheating is a must process in the vacuum tray dryer design because the drying curve and the foaming of the product are very identical through out the cabinet. During initial drying a vacuum of 40 - 80 mbar abs is used and at the time of final drying a comparatively lesser mbar abs is needed.

The vacuum tray dryer design is continuously controlled by a PLC- Programmable Logic Controller, which is an industrial digital computer which has been adapted for the control of manufacturing process. In this case it controls the vacuum and thus controls the drying process and resulting drying cycle. Later condensation process is followed in these devices in order to condense the vapor cause by any heating processes. Cold water is passed through these shelves or tray in order to bring the condensation effect.