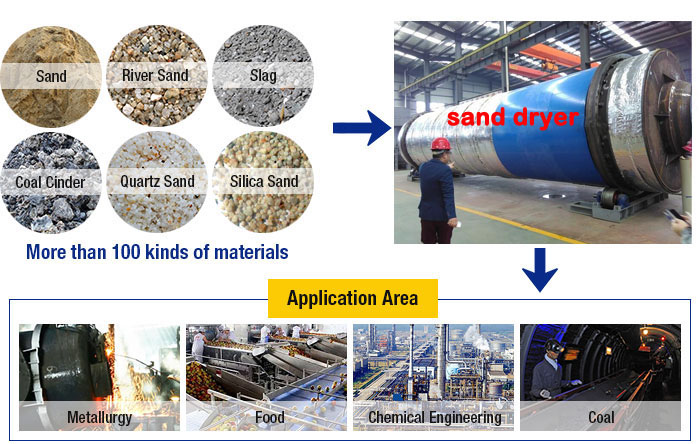

Sand Dryer Machine for Sale

A sand dryer for sale is a processing machine typically designed to dry screen and sanitize granular materials such as gypsum, silica, quartz, minerals, ores or coal. It can also be used for drying mixed sticky paste material or high moisture content. Industries include building, food, metal, chemical, coal and pharmacy plants.

Structure of sand dryer

Our three-layer sand dryer structured as a cylindrical shell fitted with two machined steel tyres rotated horizontally on four supporting rollers and two thrust rollers. At the end is a stationary combustion chamber and a feeder chamber on the other end. The shell slightly inclines toward the combustion chamber to create an opposing action from fumes on the materials undergoing combustion.

Working principle of sand dryer

Sand is transported into the dryer machine by a conveyor belt or elevator. It then goes through the feeding chamber via loading pipes. The feeding chamber is bigger so as to allow sand into the dryer. It is higher and slopes towards the cylinder. The dryer is a horizontal access located along the cylinder. Sand moves from the feeder to the cylinder passing through the dryer. Combustion occurs when gases in the dryer make contact with the material causing hot fumes to move in the same direction as the granular material as water evaporates and the drying process takes place. The walls of the sand dryer are lifting plates that create motion on sand to enable all the material to come into direct contact with hot fumes making the drying process efficient. Steam is sucked out by a high pressure draught fan and the dust is discharged through the fissure on the dust separator.

Advantages of sand dryer

- It is a three pass structure, the new technology of high temperature and fast drying.

- It is full automatic control, operates continuously, energy conservation.

- It ensure the quality of drying, but also prevents the loss of the material's active ingredients.

-

The whole system works good working enviroment, safe production.