How To Make Wheat Starch | Yeast | Soy Protein Drying

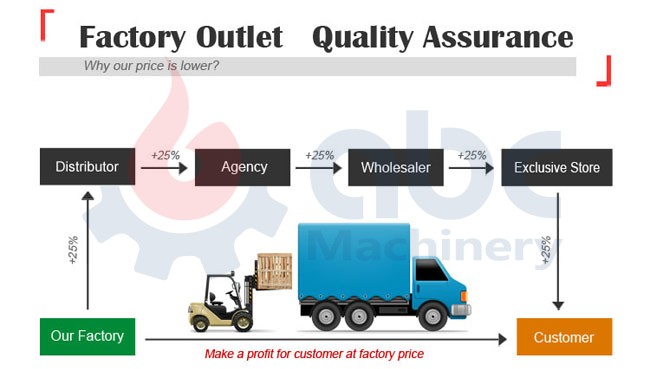

Spin flash dryer combines drying, crushing and screening all in one, it is a new type of continuous drying equipment and it is especially suitable for the drying of cake shape, paste and slurry materials(such as wheat starch, yeast and soy protein). The wet materials are dried in the drying tower only for 5-8s. The moisture is evaporated at a moment. The dried product quality has great relationship with the drying temperature, wind speed, blast capacity and the breaking speed. It can adjust the wind entering speed of the flash drying from the tangential direction. It can adjust the particle size and the final water content.

Working Principle of Spin Flash Dryer

Hot air enters into the bottom of the dryer from the tangential direction, and under the driving of the stirrer, it will form a strong rotating wind field. The materials enter into the dryer by the screw conveyor, under the intense function of the high-speed rotating stirring paddle, the materials will be distributed under the function of sticking, friction, and shearing force. The massive materials are crushed quickly contacting with the hot air, heated and dried. The dried materials are brought into the dust collecting system by the air flow, the end gas is discharged by the induced draft fan. The whole drying process is finished.

Wheat starch

Extracting starch from the wheat. Taking the wheat flour as the raw material to knead them into paste, then adding water to wash, the milky liquid being washed out is starch milk. After the purification and drying, the protein content is about 75-85%. That is mainly used in the food industry as thickener, gelatinizer, binder and starch sugar.

Soy Protein

It means the protein that the soybean contains, the content is above 38%, which is 4-5 times of the cereal. Soy protein is a kind of vegetable protein. The amino acid composition of the soy protein is similar with the milk protein, so it can go into the flash tank after the sterilization. The feeding temperature is 120-130℃, while the discharging temperature is 70-75℃.

Yeast

The fresh yeast is also called concentrated yeast or compressed yeast, the moisture content is usually about 70%. The yeast particle moisture content of the yeast being dried by the flash drier is 8-10%, under the temperature of 20℃, the yeast can be stored 2 years.