Color master batch

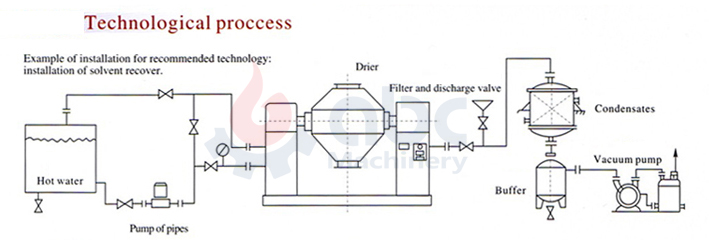

It's usually composed of three parts, colorants, carrier, dispersant. After the mixing, it is broken and extruded into granules. During the processing, the color master batch has the advantages of high concentration, good distribution and clean. The color master batch is made by the process of grinding, phase inversion, washing, drying and granulation. Only by that, the product quality can be guaranteed. The drying process usually chooses rotating vacuum drying machine.

Catalyst

The relationship between it and the reaction system has high degree of selectivity (or singleness). For example, manganese dioxide has catalytic effect in the potassium chlorate thermal decomposition and quickens the chemical reaction, but it is not always useful to other chemical reactions. In the potassium chlorate thermal decomposition, magnesium oxide, iron oxide and copper oxide can be the catalysts. Besides, one chemical reaction do not have one kind of catalyst, for example, when using the potassium chlorate to make oxygen, the red brick powder and copper oxide can be the catalyst.